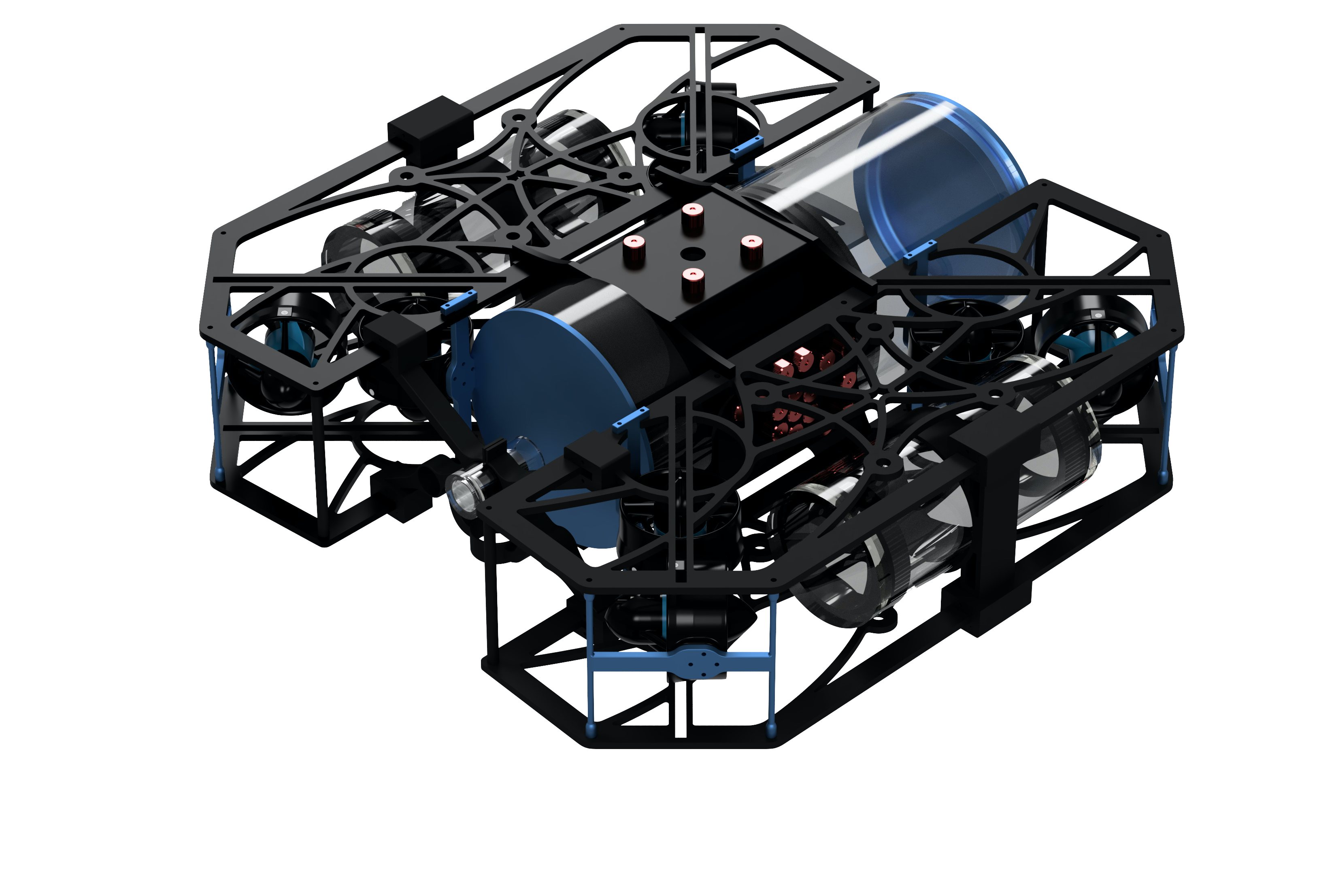

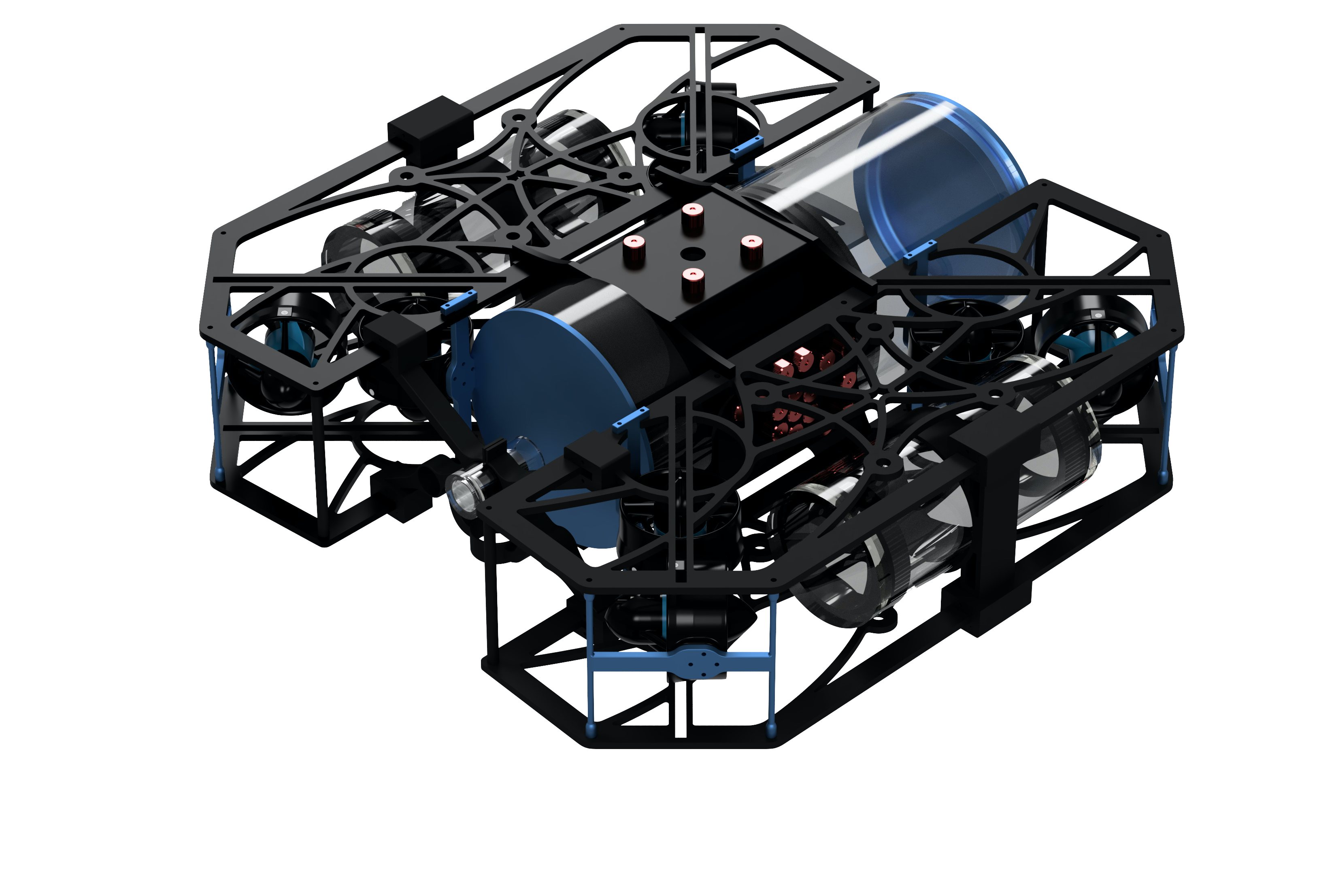

Anchovy is BeaverAUV’s fifth-generation autonomous underwater vehicle, developed for the 2025 RoboSub competition. Building on the successes of previous AUVs, Anchovy features a robust and modular design that makes component access, repair, and upgrades easier than ever. Its large acrylic pressure hull, sealed with anodized aluminum end caps and protected by a waterjet-cut aluminum frame, ensures durability and watertight integrity. Anchovy is equipped with eight thrusters and a dynamic trim system, providing precise control and stability in all axes. Powered by an NVIDIA Jetson computer and a reliable power distribution system, it supports up to five hours of autonomous operation. Anchovy’s sensor suite includes a high-resolution underwater camera, a Blue Robotics depth sensor, and a VectorNav IMU, enabling advanced navigation and perception. Scroll down to learn more about Anchovy’s mechanical, electrical, and software systems.